During lead-free soldering, besides the wet sponge, there are other ways to clean the tips. Which way to adopt depends on seriousness of the contaminant on tips, and technology of maintenance and soldering method.

Below instruction would help you to choose the most convenient way to clean your tips. For example:

Slightly wet sponge (not drown by water) is an effective way to clean under the condition of clean tips. Replace the sponge regularly and use deionized water. But there is weakness, when using old version soldering system, due to lack of quick heat feedback, the temperature of the tip will drop after touching the sponge, and the working temperature only resumes after several seconds. Another shortcoming is, hot and cold shock at the same time will damage plating coat.

Brass cleaning ball is a substitute of sponge, requiring not so much maintenance, and will not lower the temperature of the soldering tip. Which makes the brass cleaning ball more suitable for the soldering iron with slow heat feedback. But the weakness is the residual will adhere to the ball which has no anti-tin splash cover and splash to the PCB. Moreover, the stand containing the brass cleaning ball should be heavy enough to avoid shake during operation.

Metal brush is another invasive cleaning way. Use it with gentle force can completely clear and clean the contaminant without great damage to the soldering iron tips.

Soldering iron tip reluctant is a chemical cleaning way which shall re-tin to the soldering iron tips. When all other methods not effective, reluctant is alternative that works. Surely over-dosage of reluctant would cause server damage to the plate coating of the soldering iron tips.

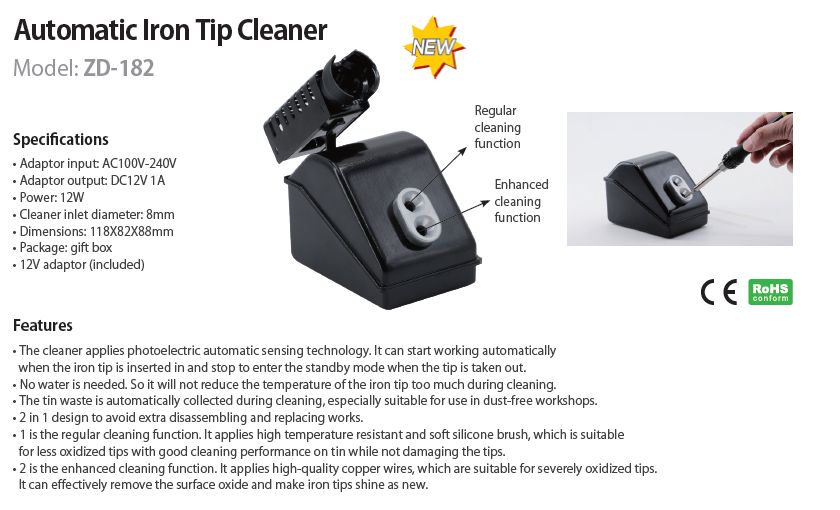

In order to make your work more easy and convenient, Zhongdi represents you an automatic iron tip cleaner ZD-182 which is newly developed. Please write to us zhongdi@zhongdi-solder.net for more info.

Post time: Feb-25-2022